Usually rose buds should be harvested before they open, that is, when the longitudinal diameter of the bud is 3 times that of the calyx, the yield is reduced too early, and the quality of flowers that have bloomed too late is affected. During the flowering period, choose strong and plump buds to pick them, and pick the petals after the other thin and weak buds are fully opened. Flowers that bloom sporadically at other times will also be fully opened and picked after the petals are picked. Rose drying equipment, while drying roses, you can also collect rose cell fluid, killing two birds with one stone. Today we give a brief introduction to the air-energy rose dryer.

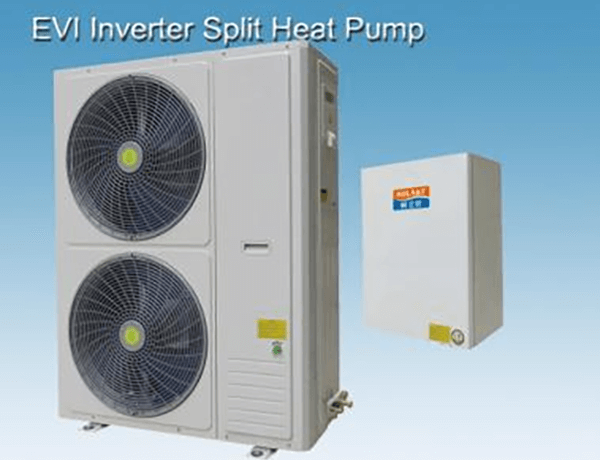

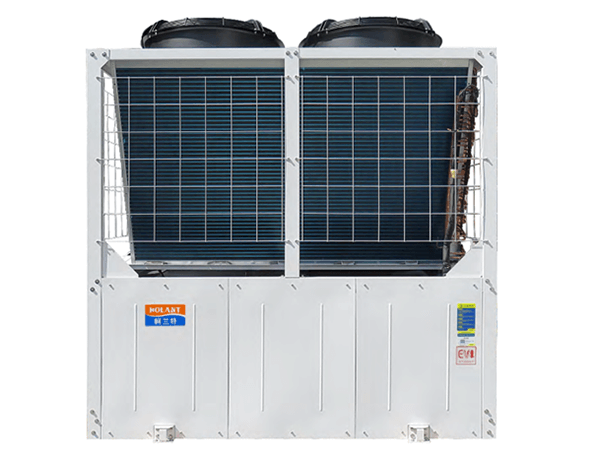

Kolant air-energy rose heat pump dryer uses low temperature, enhanced circulation wind and strong humidity discharge for drying, which can ensure the natural color of roses, full shape, no damage to the flower shape, no damage to its natural medicinal effect, and no loss of nutrients. The heat pump The dryer has a high degree of automation and does not require a dedicated person to take care of it. The drying process is all controlled by a microcomputer.

1. Pretreatment of roses before drying

Some industry insiders carry out color protection treatment before drying roses. The specific implementation method is to change the pH value in the cell fluid of the flower material or to complete the brine at high temperature to increase the stability of the pigment, and to kill or passivate the material. The enzyme activity is used to protect the color.

2. Rose material

Put the rose stamens into the material in layers. The 14P air energy heat pump drying integrated main machine is equipped with a polyurethane insulation drying room of about 50 cubic meters. One batch can be placed in about 2,000 kilograms of fresh flower stamens. The entire drying room can be loaded with 8 material trucks, each material truck is divided into 12-14 layers, with a layer spacing of about 8-12cm. The material truck must use 304 stainless steel screen to avoid production pollution to the material.

3. Understanding the parameters of roses

The wet and dry ratio of roses is about 4:1. Try not to exceed the recommended loading capacity when loading, so as not to affect the shape of the flower and the quality of the dried flower.

Roses dry. Push the material truck into the drying room, close the drying room door, turn on the drying power supply, and set drying parameters on the heat pump dryer microcomputer control board. Parameters can be adjusted based on customers’ previous drying experience. For example, set 5 segments on the parameter board.

4. The reference process of roses (equipment from different manufacturers and unused equipment (open and closed), as well as different project locations, and the drying process is different, for reference only)

Stage 1; adjust the drying mode, this stage does not drain wet, dry for 1 hour

Stage 2; set the temperature to about 50 degrees, then start dehumidification and remove the humidity to 40%

Stage 3; raise the temperature by 10 degrees and reduce the target humidity to about 30%

Stage 4: The temperature remains unchanged and the target humidity is reduced to 20%

In the 5th stage, the temperature can be adjusted appropriately and the target humidity can be reduced to 15%. Check the dryness of the roses.

While drying, pay attention to the water connection tray in the drying room. If the water is full, change the water connection tray in time. Keep the water removed well. This is the raw material for extracting rose essential oil.

In fact, the process of drying roses is relatively complicated, and it changes greatly to temperature and humidity, so it is not easy to make high-quality roses. When the rose is initially dried, the temperature at the beginning should not be too high, and it is OK to 60-70℃ later. During the drying process of roses, you should observe the changes in color and moisture at any time through the observation hole. The moisture discharge is good and the color is bright. The lowest layer of roses should be dried out before they are out of the box. After the appropriate moisture content is released, it will be spread out and dried. Can. Because the surface temperature of roses is not too high, the chlorophyll changes less, the color is green and resistant to hiding, the aroma is less loss, and the drying is even; at the same time, due to the rapid evaporation of water, it is easy to form porous, the product has good rehydration properties, and the contents of the tea are contents. Easy to dissolve.