Competitive Advantage

Technological Superiority

Inverter technology adaptive Load Variation Demand for Perfectly Comfortable Temperature

Kolant inverter system uses a full DC inverter design, allowing the compressor to adjust continuously and across a wide frequency range. It can precisely regulate the refrigerant output based on indoor and outdoor load, ensuring constant water temperature and compressor speed. This eliminates the need for frequent start-stop cycles, leading to greater energy efficiency and providing users with a comfortable, energy-saving heating experience.

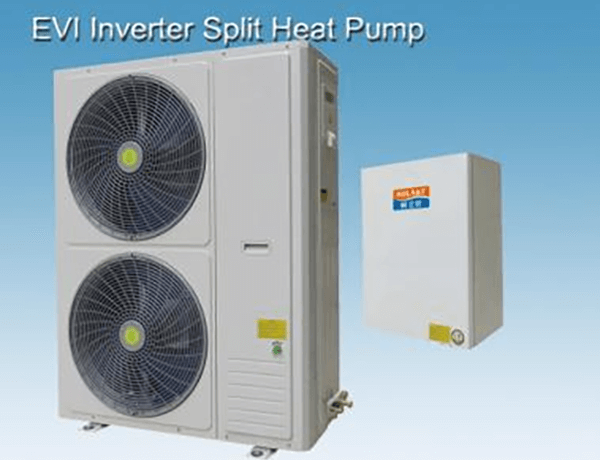

EVI Technology, Significantly Enhancing Low-Temperature Heating Capacity

EVI (Enhanced Vapor Injection) technology injects a large amount of gas-liquid mixed refrigerant during compression, significantly increasing the discharge volume at low temperatures. Combined with DC inverter control technology, this further enhances low-temperature heating capacity and energy efficiency. Even in extremely cold environments, such as -35°C, it maintains strong heating performance.

Compressor Non-stop at defrost and Silent Defrosting

Compressor non-stop technology reduce the whole defrost processing time and satisfy the user requirement for room heating cooling and domestic hot water at the short switching time. This will improve user comfort feeling greatly.

During defrosting, the system reduces the compressor frequency and minimizes the reversing pressure difference across the four-way valve, significantly reducing the noise produced during valve switching.

Inverter Noise Reduction, Creating a New Realm of Comfort

When the heating reaches the set temperature, the system automatically switches to a stable operation mode, reducing the operating frequency of components, which greatly reduces operational noise.

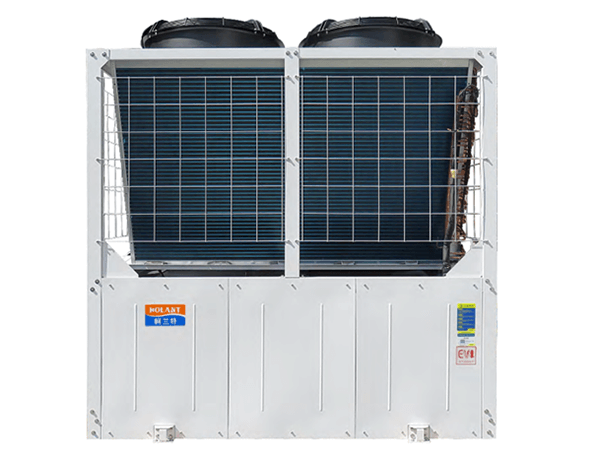

Production Inspection Process

Total about 30 process for one heat pump to ensure the quality and reliability.